YOUR BUSINESS AUTHORITY

Springfield, MO

YOUR BUSINESS AUTHORITY

Springfield, MO

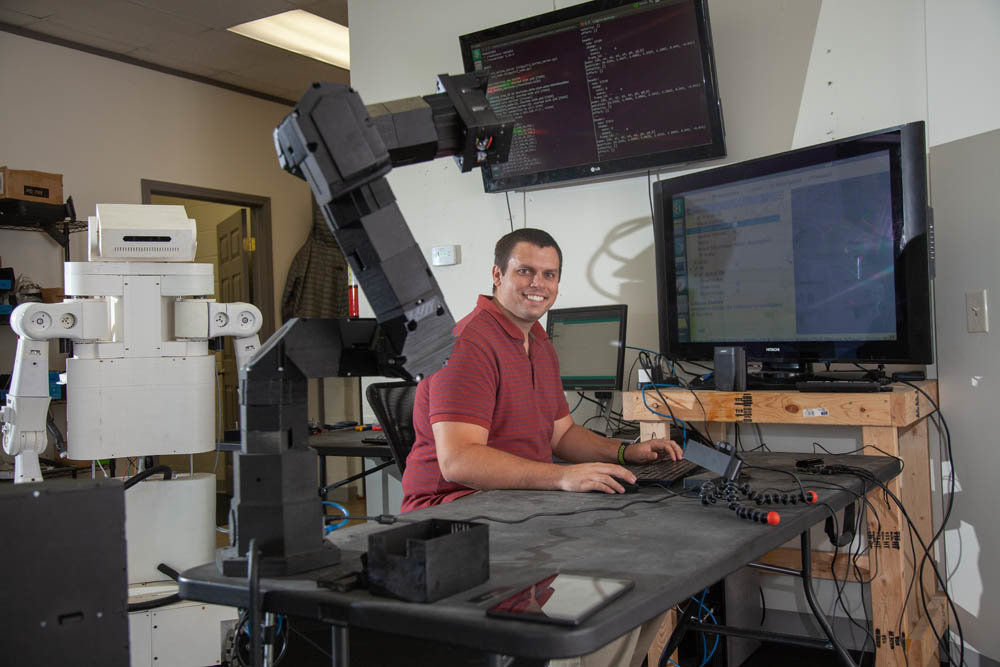

They’re looking into the future at Slate Robotics Inc., one with machine companions.

The company’s owner, Zach Allen, thinks the technology will be available to consumers for chores around the home by the end of 2020, when Slate Robotics is planning to release its third generation model, the TR3.

“We have something in the works right now,” Allen says. “By the end of the year next year, you’ll be able to buy one of our robots for household chores.”

He’s thinking a step up from robot vacuums. The hope is that TR3 will be able to complete about 90% of daily household tasks, like making coffee, feeding pets, setting the table and doing laundry.

Allen’s forecast to market comes two years after he launched the company to develop personal robots and following a three-year stint with Pension Consultants Inc., the financial planning company founded by his father, Brian.

While working as a software developer at Pension Consultants, Zach Allen became interested in designing robots and went to the internet to find a model to purchase for experimentation.

The search went unfulfilled.

“Robots are very, very expensive,” Allen says. “The cheapest options were between $60,000 and $70,000.”

Drawing inspiration from those models, along with some design aspects from a $400,000 model, the development for Slate Robotics’ original TR1 model was born.

In development

The TR robot models are named after philosopher John Locke’s tabula rasa theory, meaning “blank slate,” Allen says. TR1 took a couple of months to complete before it was released in September 2018.

“It was mostly based on what I had seen on the more expensive stuff,” Allen says of the two-armed robot that moves on a wheeled platform.

The TR2, released this summer, took two weeks to build and features a single arm with a mounted camera, like the original, and stands 47 inches tall. It runs on coding written by Slate Robotics. It can pick up objects just over 2 pounds, according to the company’s website.

Videos posted online show examples of the TR2’s capabilities, including one where a treat is given to his dog, Dublin. Another shows Allen providing a guide on how the code interacts with the robot’s five joints on its arm.

Allen programmed low-level code and interfaces into an Xbox controller to communicate with the TR2, and he says the process involved several months of iterations and improvements.

Along with videos, all of the code sources for the TR2 are posted on GitHub, an open-source website for developers.

Slate Robotics, which operates at 210 W. Sunshine St., Ste. C, has sold several TR2 models to date, Allen says, mostly to developers with machine-learning backgrounds. The most notable was by the University of Montreal in Canada.

Allen says he’s approached Springfield-area universities about featuring the TR2 in robotics programs, but the slow-moving grant and budget process make outlets like GitHub more desirable to improve specifications and accuracy.

On its website, Slate Robotics currently lists its TR2 model starting at $4,000. Allen says the company is focused on filling current orders and working on design improvements for the pending TR3 model.

Slate Robotics received its initial funding from Allen’s father.

“It was enough to get him started but not enough to make him extremely comfortable,” Brian Allen says, declining to disclose the amount invested.

The elder Allen has a board seat but says he has little to do with the company operations. He sees growth potential in the industry over the next 25 years.

“Robotics, in general, is probably the internet of his generation,” Allen says of his 26-year-old son.

He compares the robotics industry to the rise of personal computers, saying there’s a delay in adoption for newer technology until pricing becomes more reasonable for consumers.

“You’re using it first at the largest scale because of the investment, but eventually the cost will come down,” Brian Allen says.

Robots rising

Robotics is a burgeoning industry.

North American robotics sales were up 7.2% in the first six months of 2019 compared with the same time last year, according to the Robotics Industries Association, with companies ordering 16,488 robots valued at $869 million.

Current robotics sales are dominated by the automotive sector at 83%, with food and consumer goods – the space Slate Robotics works in – currently only making up 3%, according to the RIA report. The association previously reported in 2011 that food and consumer goods robotics would be used in warehouse distribution systems and testing consumer goods for quality control.

Industry analysis reporting firm Market Research Future predicts the global robotics industry will hit $93 billion by the end of 2023. MRF predicts consumers will use robotics primarily in the medical, entertainment, logistics, manufacturing and public safety fields.

Working with robotics comes with its challenges, like manuals written only in Chinese for parts, says Tavian Riebold, an electronics engineering intern at Slate Robotics.

Riebold has been with the company for nearly a year after a newspaper ad piqued his interest as a self-described electronic hobbyist. He and Isaac Feemster, a 3D printing technician, comprise the staff working with Zach Allen.

The robots are 3D-printed on-site and assembled by the Slate Robotics team.

“Our overall goal is bringing robotics into people’s homes and having personal robotics,” Riebold says.

A franchise store of a Branson West-based quilting business made its Queen City debut; Grateful Vase launched in Lebanon; and Branson entertainment venue The Social Birdy had its grand opening.

$2M in tax credits awarded to SWMO nonprofits

Baldwin, Lathan to chair United Way campaign

Produce recall impacts food sold at Walmart, Aldi and Kroger

Mixed-used development proposed in KC area

Tax deduction program for farmers set to launch

Report: Panera explores sale of Caribou Coffee, Einstein Bros Bagels