YOUR BUSINESS AUTHORITY

Springfield, MO

YOUR BUSINESS AUTHORITY

Springfield, MO

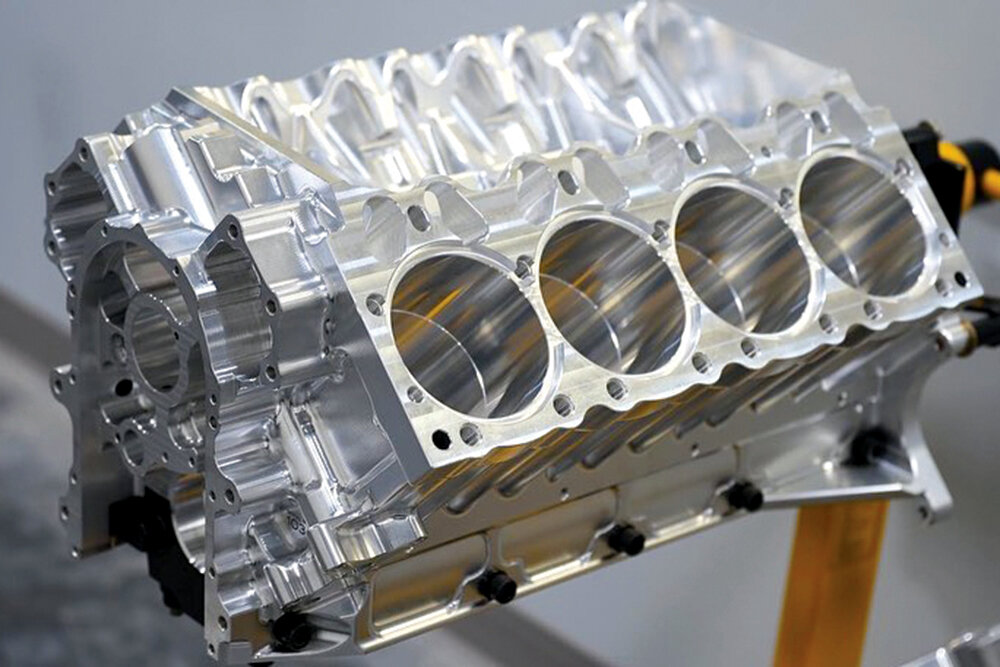

The Point One team manufactures a crucial component for the world’s fastest-accelerating vehicles – Top Fuel dragsters and funny cars – that exceed speeds of 330mph in just 3.5 seconds. These engine blocks, precisely machined from a 700-pound billet of 6061 aluminum, represent over a year of development and testing, ensuring repeatability in a sport where extremes are redefined regularly. The local product is at the heart of supercharged, nitromethane-fueled engines, embodying the pinnacle of performance in professional drag racing.

SBJ: How did Point One get into the drag-racing industry?

Shannon Strother: While we have a great relationship with many of the pro teams, Brad Mason of AB Motorsports, who is originally from Sparta, grew up in the local racing scene and knew (Steve) Brallier from racing during that time, who went on to found Point One. Brad knew that we were working on some related projects and inquired about us making a block for their class, and soon after we were committed to making this project come to life. We started making this block in 2021 and, after receiving approval from the NHRA late that year, were first used in competition during the 2022 racing season. Hundreds of competitive laps later, with many round wins and several event wins using Point One blocks, the 2023 NHRA Funny Car Championship was won by Matt Hagan with our block in the car.

SBJ: How does the billet block function?

Strother: The block is what they build the engine around; it’s what holds the series of violent mini explosions together to propel the car. The part we make has been the same basic size for over 40 years, and they keep making the track shorter. It used to be a quarter of a mile; now it’s 1,000 feet. Sometimes, the engine blows up before completing one run, but typically they will run them six to eight times or more before they freshen the engine. When they do that, the team will decide to take it out of service or keep on running the block or make repairs. Ideally, they’ll run each block 30 to 50 rounds, if they can.

SBJ: Who else makes these blocks?

Strother: Only a few others are making these across the United States – perhaps only two others.

SBJ: How does making the blocks here in the Ozarks impact the local economy?

Strother: According to a 2023 (Specialty Equipment Market Association) study, the racing and after-market industry have a total economic output of $336 billion in the U.S. alone, including $104 billion in wages and $41 billion in taxes paid. The teams we support are high-end, high-budget teams and spend millions per year on each car to race in these classes. This directly contributes to our local economy in many ways, and in our case specifically fostering the personal growth and success of the P1 team. We are finding great local talent here but also attracting people from out of state. In just the last two years, we have attracted and relocated four new positions from out of state. We are going to continue to grow and expect our growth to be double digits for many more years. I expect we will double our size in the next two to four years.

Led by a team of gardening experts, Harvest Grow Supply offers know-how alongside more than a thousand products.