YOUR BUSINESS AUTHORITY

Springfield, MO

YOUR BUSINESS AUTHORITY

Springfield, MO

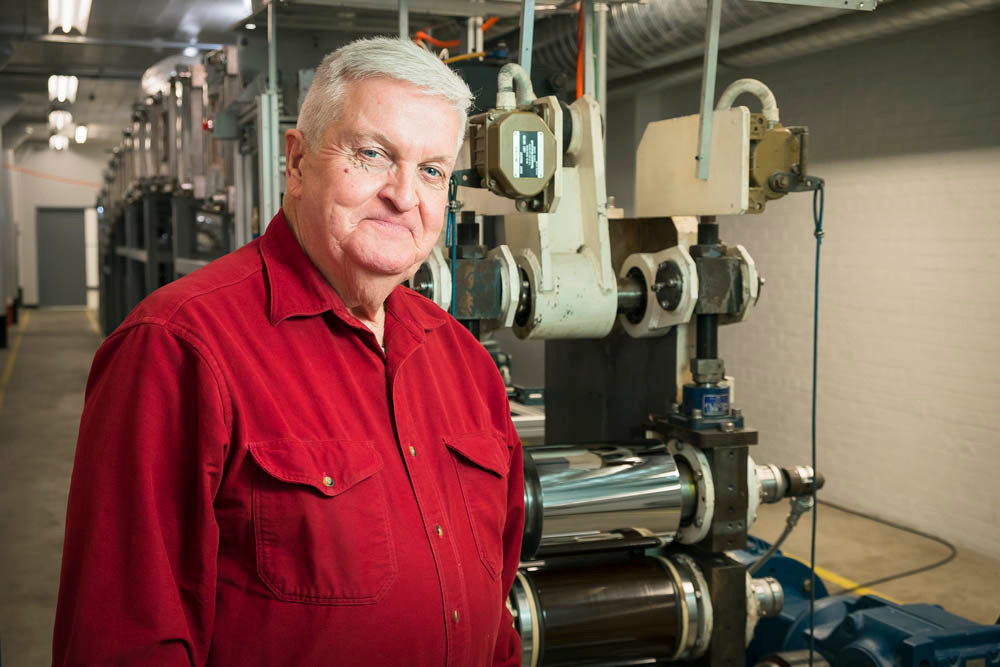

When the compact cassette tape was invented in the 1960s, National Audio Co. jumped on board, and recorded decades of success building blank tapes from purchased components. This was before compact discs and digital downloads took over the market. Owner Steve Stepp held on to the format long enough to see a resurgence of popularity around 2007.

As one of the only companies now left in the industry, Stepp said thousands of record labels began contacting his office to not only sell them cassette tapes, but also handle the duplication.

The only problem: The manufacturers of the components that make the cassette tapes had all gone out of business or moved on to other pursuits.

“We knew that our suppliers of cassette tape in South Korea were going to give it up, and we bought their inventory at the end,” he said. “We knew we were going to have to make tape or go out of business.”

Stepp found domestic manufacturers that could make the plastic bodies and cases for the vintage medium, and local print shops could make the labels and paper inserts, but the actual tape the audio is recorded onto was nowhere to be found.

When Chief Technician Bob Coverston was hired many years ago, he told Stepp the last thing in the world he wanted to do was manufacture tape, but now that’s exactly what he’s in charge of doing.

“There is no other source,” Coverston said. “We have exhausted all possibilities.”

Tape production line

The team searched the globe, and contacted old industry connections to cobble together the pieces of a compact cassette tape factory – with all of the equipment originating from the 1960s and 1970s.

“If it hasn’t worn out in 50 years or 60 years, it’s not going to wear out now,” Stepp said.

National Audio purchased a 60-foot-long production line that had been used most recently to make magnetic strips for credit cards, Stepp said, which is a similar product to an audio tape.

“I don’t disclose what we spend, but it was expensive. We have generated it out of our operating revenues,” he said. “I wouldn’t say anybody’s going to take home a lot of cash at the end of the year, but we’ll be in good shape next year.”

The equipment has been assembled on the second story of National Audio’s 309 E. Water St. building. Record label representatives and musicians will be invited to observe the manufacturing process while touring the factory, Stepp said.

“We were able to find some retired people who had been in that business, and bring them in and pay them to work with us a week or two, to teach us whatever we needed to know,” he said.

Stepp found a couple of retired cassette tape factory workers and hired them as temporary consultants to train him and his staff. The basic procedure to making cassette tape hasn’t changed in decades.

Stepp said National Audio secured a supplier of 6.5-inch-wide rolls of thin, translucent polyester film. The Springfield staff take raw ferric oxide – which is basically iron rust powder – and polyurethane beads and grind it into a fine powder, which gives tape its brown appearance.

“That mixes up with a few other chemicals that make it disperse smoothly – that’s made into what’s called a ‘slurry.’ And that is about the consistency of a thin-downed latex paint,” he said. “Then that’s applied in a very, very thin coating on the polyester-based film.”

To dry the coating, fresh air from outside is filtered, heated and pumped into the machines, kept in a dust-free environment.The tape is polished before it completes the path, being gathered onto a large spool.

“Then we take the 6.5-inch wide ‘jumbos’ off of the coating line and put those on the slitters,” Stepp said.

The outer quarter inch is trimmed from each side for quality control, he said, and the jumbo tape is cut into 40 rows of eighth-inch wide strips. Finally, the strips are rolled onto 12,500-foot-long spools – which National Audio can use to make cassette tapes or sell to other cassette manufacturers.

Coverston oversees production and laboratory product testing.

Industry appetite

The spools are used as the recording media for the 3,300 record labels that depend on National Audio for new cassette tapes. The local business has attracted many indie labels and major labels – such as Sony Music Entertainment, Capital Music Group and Universal Music Group – as well as popular bands Pearl Jam, The Smashing Pumpkins and Metallica. The labels and groups needed a business to duplicate their studio recordings.

Most notably, and recently, Stepp said the soundtracks for both “Guardians of The Galaxy” movies have been reordered by Disney Music Group, totaling hundreds of thousands of copies.

“We’ll have between 200 and 400 releases working in-house all the time, from one kind of music to another,” he said.

Though cassette tapes are thought of as a thing of the past, global sales have been making somewhat of a comeback – and represent a bright spot in the music market.

Album sales in all music formats dropped 17 percent last year to 200.8 million units sold, according to Nielsen Music data cited by Billboard. Although a tiny fraction of the total, cassette tape sales grew by 74 percent to 129,000 units sold in 2016. Additionally playing into the vintage appeal, vinyl album sales were up 10 percent 13.1 million units.

Stepp believes National Audio is well positioned to lead during the resurgence.

“We’re able to make the tape that we need and be able to also supply tape to our competitors all over the world,” Stepp said. “It’s to our interest to keep them going and keep the format active and strong.”

Alair Springfield is first Missouri franchise for Canada-based company.